Our Production and Warehouse

Renewable Energy

Since 2020, we have based our electricity consumption on 100% renewable sources either produced by ourselves or through renewable energy certificates (RECs). By the end of 2024, 54% of our Scope 1 and 2 energy consumption (excluding logistics) came from renewable sources, either through our own production or renewable energy certificates (RECs). Capital expenditure is approved to bring that share to 92%.

While this is having a positive impact on CO₂ reductions, we keep a keen focus on improving efficiency and installing solar panels, heat pumps, and electric boilers, aiming for at least a 60% reduction by 2030 compared to 2019.

Energy Efficiency and Consumption

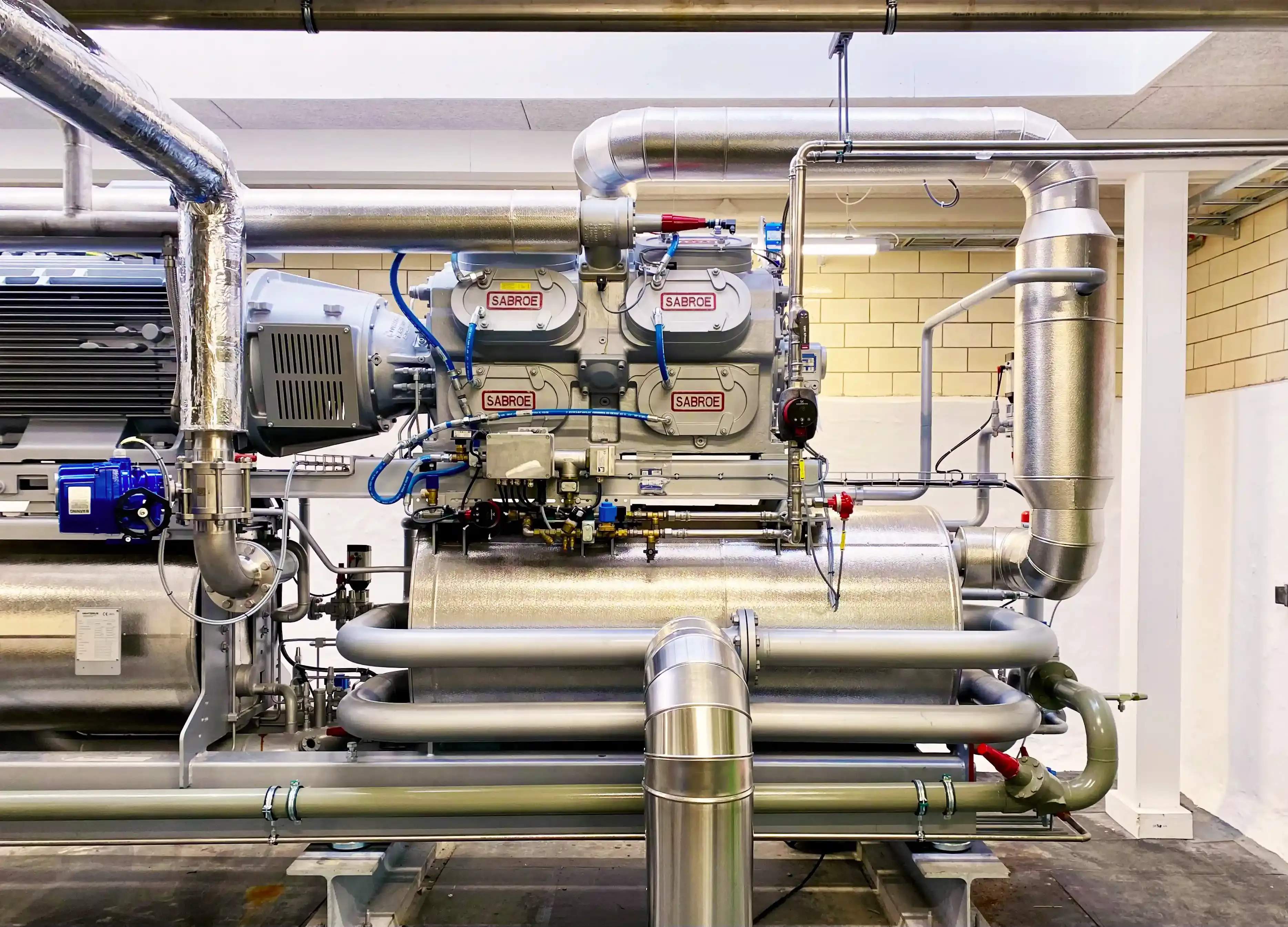

We focus on energy efficiency at all our production sites, and the majority of our sites have already implemented heat recovery from processes such as brewing, cooling, CIP and compressors–laying the foundation for future heat pump use.

Monthly reporting from each site allows us to track and document CO₂ emissions, covering electricity purchases, own electricity production, fuel and refrigerant use, and heat and cooling-related energy purchases.

Water Management

We aim to reduce water withdrawal to 2.5 hl/hl of beverage produced by 2030, with a lower target of 1.4 hl/hl for carbonated soft drinks. In 2024, our average was 3.2 hl/hl. All water is treated before discharge primarily at public wastewater treatment plants. We are not located in high water risk areas, however, access to clean water remains a priority.

Our initiatives include water reuse circuits, additional metering devices, and equipment upgrades. In partnership with WWF, we are restoring freshwater ecosystems in Latvia, including educational components for employees and communities.

Waste Reduction

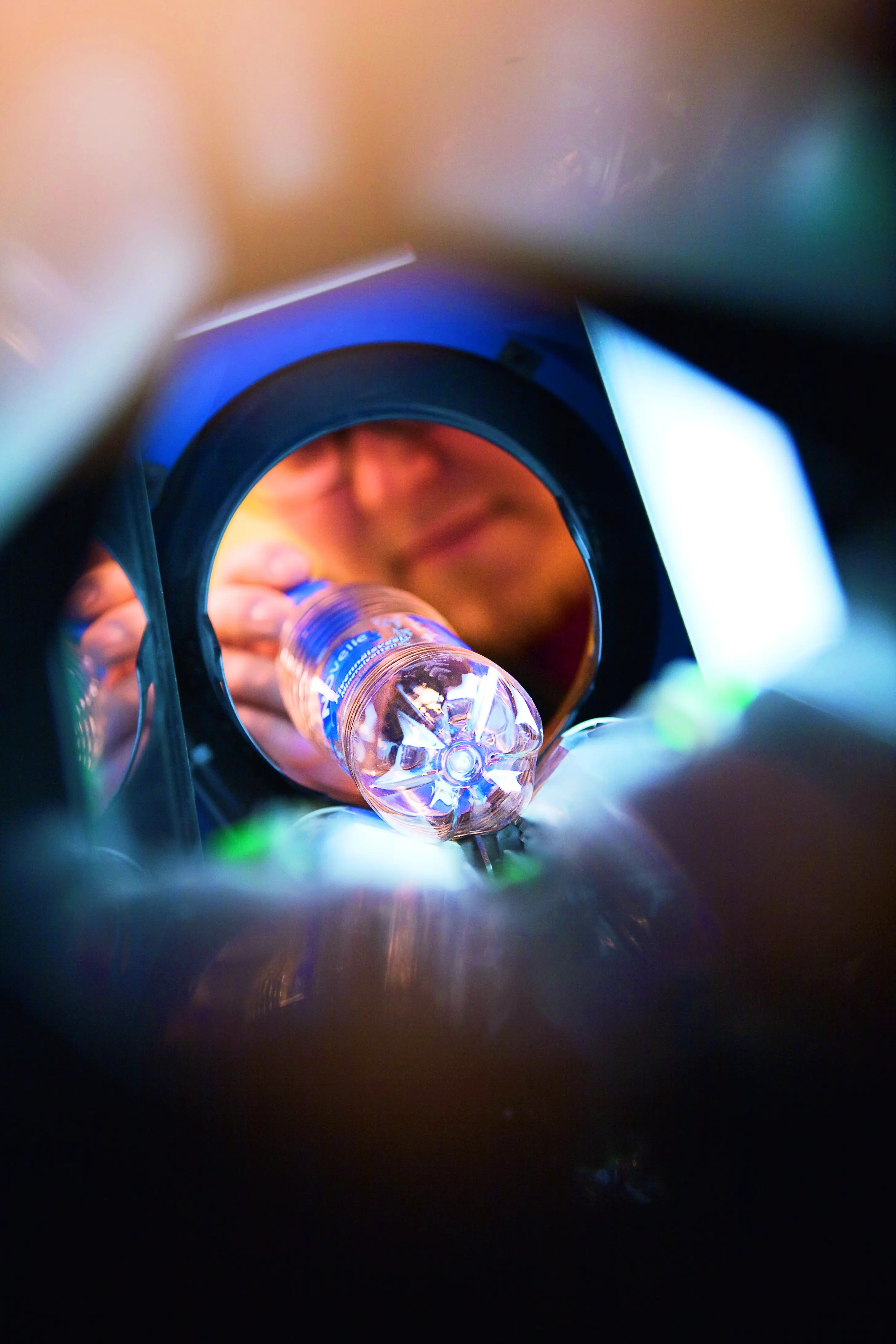

Circularity is key to reducing waste in our operations. We recycle around 90% of production waste, and all organic byproducts and organic waste are repurposed for food, feed, or biogas. We are committed to increasing recycling rates and reducing landfilled waste year over year.

Proper treatment of waste, including recycling, is ensured via well-established collection and sorting in line with local regulations. We work with our suppliers to enhance delivery systems for incoming goods.

Health and Safety

Health, safety, and well-being of our employees are our top priorities. We are boosting our efforts in 2025 and aim for a 100% safety culture by 2030. We have actions and targets in place encompassing targets for minimizing lost time incidents, reducing their severity and preventing any form of harassment, bullying, or discrimination. Our goal is to foster a behavior-based safety culture.

Our employees receive regular training, and safety procedures are in place for handling hazardous substances and processes, emergencies, and non-conformities. We are organized with health, safety, and wellness committees with representatives from both management and employees.

Certified Food Safety

Food safety is essential to our business, which is why 99.9% of our production is certified to leading GFSI standards like FSSC 22000, IFS, and BRC. All production sites adhere to strict international standards and Good Manufacturing Practices, covering risk assessments, recalls, food fraud, and consumer feedback.

We invest in quality and safety with precise process control and robust systems for customer inquiries. Our sites hold ISO certifications across food safety, quality, environment, and occupational health and safety.

We track key metrics such as complaints, recalls, and supplier compliance on a monthly basis with the clear goal of eliminating risks related to allergens and food safety. In 2025, we will align Group-wide targets across all markets and continue to raise our quality standards.